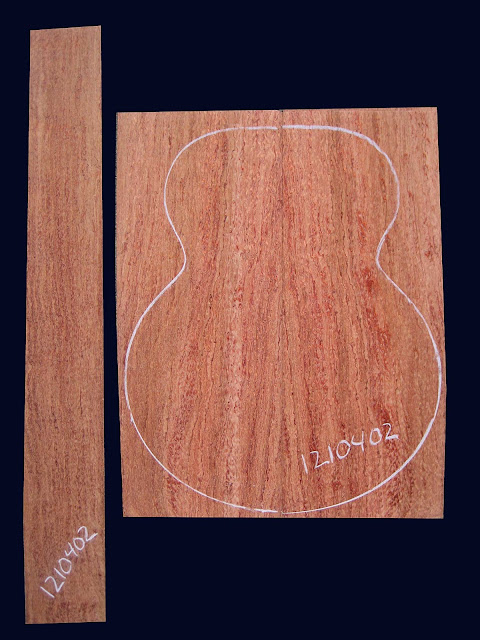

The task of bending the sides gave some cause for concern when I decided to use my one and only set of Bubinga recently. I was already aware that bending this wood can pose challenges, and on researching the topic it became apparent that unhappy accidents are commonplace. To mitigate the potential for disaster, I took the cautious approach and doused the sides in Supersoft veneer softener and shrouded them in plastic for a couple of days before unwrapping them and allowing them to dry completely prior to bending them.

What I've learned about this wood is that there are several Guibourtia species marketed as Bubinga, which perhaps explains the variety in appearance encountered between individual examples. With the sides successfully bent to shape, I've concluded that either the precautions I took contributed to my success or that the particular variety I'm working with tends to be less troublesome than other species. With Bubinga now listed on CITES and therefore no longer available in this country, I guess I should count my blessings as I forge ahead with this guitar, safe in the knowledge that I'll never have to deal with it again.

Cheers

Pete